Paid Advertorial

The onion factory of the future must perform as reliably as possible with minimal physical labor. The Eqrader sorts onions at high speed by quality, size, weight, shape, and color. The machine is specifically developed for and in cooperation with the onion industry and uses artificial intelligence to categorize onions. Advancements have been made over the past year based on client feedback. Time for an update.

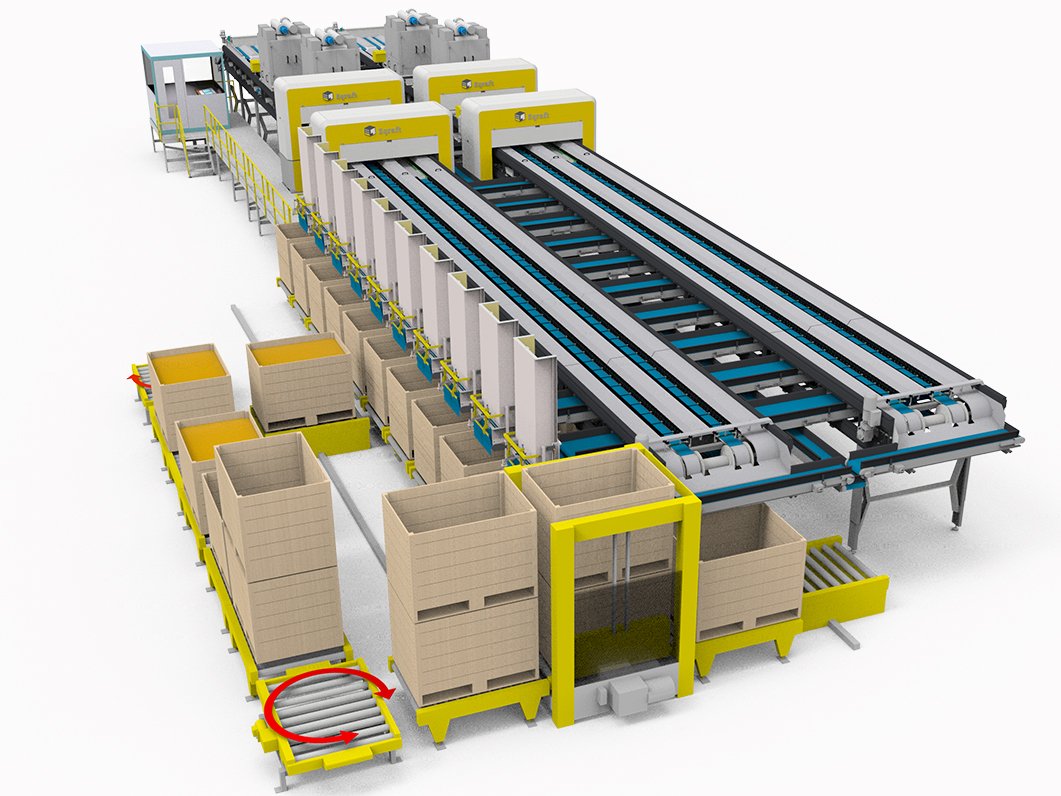

The Eqrader places individual onions in cups, where they’re then cleaned by a Modesta dust extraction system that blows away onion skins and dust. The machine uses the dark chamber principle and near infra-red for internal inspection of the onion and rot-detection. A tilt section ensures that the onion is turned and checked on all sides to determine color, skin condition and size. The grader then weighs and categorizes the onions, so they can be crated, using different dispensers that can be adjusted according to customer demands.

Mechanical optimization

Bas Pomstra, head of research and development at Eqraft, tells us which mechanical improvements have been made since the first client started using the Eqrader in May 2017. First, the so-called “V-band”, which places the onions in soft cups for gentle handling and guides them through the machine, was optimized to allow a more streamlined transition. “An average of 75% to 90% of the cups are filled,” says Jim Hoogzand of Dutch seed propagator HOZA, who worked with the machine in the past year. Furthermore, improvements were made to the tilt section, which ensures a 360-degree check of the onions, and the integrated cup washing system, which automatically washes the cups. Lastly, the software of both the interface and the Q-Eye camera were adjusted to fit the customer’s needs better. Two additional cameras were added, and the focal distance was fine-tuned, which means there are now six highly-focused cameras aimed at one track, ensuring even better coverage of the entire onion.

Artificial Intelligence

Besides mechanical improvements, significant progress has also been made in the development of the machine’s neural network. The neural network is a self-learning system that receives data based on a classification model that is used to determine the quality of the onions. The external quality characteristics are divided into categories and subcategories. The neural network is being ‘taught’ to sort the onions based on these categories. This will enable the user to sort batches meeting certain quality characteristics required for a particular customer or country.

In order to achieve optimal grading, the neural network needed to ‘learn’ how to classify the onions. The first test results were positive. After ‘training’ the machine with 80,000 onions, the Eqrader was put to the test by having it sort 20,000 onions. The results: it was able to perform with at least the same quality as traditional sorting. Eqraft is developing the neural network together with the onion sector, collecting as many red and yellow onions in all categories as possible. “The more data we have, the smarter the machine gets,” says Bas.

The Factory of the Future

While employees and onion traders may have different opinions on the quality of an onion, the Eqrader always sorts consistently and according to the same standards. Furthermore, it does this much quicker than a human could: ten onions per second per track, with minimal physical labor. Advantages of the Eqrader include user and product friendliness, low maintenance costs, and use of the newest vision technologies. It enables order fulfillment based on niches or volumes due to the known details of each inspected onion. Eqraft’s overarching software: Eqontrol, enhances communication and control throughout the production line and enables a “smart onion factory”.

For information:

Norman “Snap” Keene (U.S.)

E-mail: norman.keene@eqraft.com

Harm Geurs (North America)

E-mail: Harm.geurs@eqraft.com

Meet Eqraft at the following events:

July 18-21 NOA Summer Convention, Bakersfield (US)

July 21-24 US Dry Bean Convention, Bonita Springs (US)

October 10-20 PMA Fresh Summit, Orland Florida (US)