OnionBusiness.com’s Sherise Jones was on the floor at PMA Fresh Summit and visited with many folks in the onion industry, including our friends at Volm Companies. At the packaging company’s booth, Sherise was given a terrific first-hand look at the new Bag-2-Paper technology by Volm Communications Manager Marsha Verwiebe, and Sherise said the equipment and material are cutting-edge.

Volm’s expertise in the packaging world has been recognized for decades. The 65-year-old company, which is headquartered in Antigo, WI, and has operations in both the United States and Canada, stays ahead of the curve by providing the fresh produce industry with the very latest generation packaging equipment and materials.

“Our efforts including staying in touch with trends and future needs of the packer such as traceability, automation, productivity and sustainability,” a Volm brochure reads. “As a single-source supplier, we offer complete expert packaging consulting services, from package design and graphic development to full-line equipment integration.”

That includes the revolutionary Bag-2-Paper, which was developed in response to the “wishes and demands of our customers” and “… a close eye on developments in the market.”

Bag-2-Paper technology for the vertical packaging machines makes use of “100 percent paper, without plastic coating, and therefore 100 percent suitable for recycling.” And, “on top of that, the packages can be closed without sealing and are packed incredibly fast on our vertical packaging machine. Our revolutionary Bag-2-Paper machine can be used to sustainably pack your dry products, such as potatoes, onions, garlic, shallots, nuts, seeds and flower bulbs,” the brochure notes.

The mechanics of the new equipment start with a roll of paper that is inserted into the vertical packaging machine. The paper is perforated with holes to match the user’s package design, and the machine applies a label over the holes to close the package later.

A vertical closing strip is applied before the paper is folded around the filling tube, and a special closing system finishes the bag by pressing the paper and label together, cutting it off at the same time.

It’s a great melding of performance and speed. The brochure notes that thanks to the vertical packaging technology, the Bag-2-Paper machines keep working at the speed the user is accustomed to. And because there’s no heat applied to seal the package, the Bag-2-Paper machines are very energy efficient.

“This is not only good for the environment, but you will notice this in the costs as well,” the brochure says. “The machine is fast and easy to change over if you still want to use the machine with your plastic packages.”

The benefits of 100 percent paper packages are undeniable – “they are 100 percent suitable for recycling,” of course, whereas traditional packages often have a plastic coating on the inside which makes them unfit for recycling. It also takes more energy to seal plastic-coated packages, another impetus for the Volmpack Bag-2-Paper.

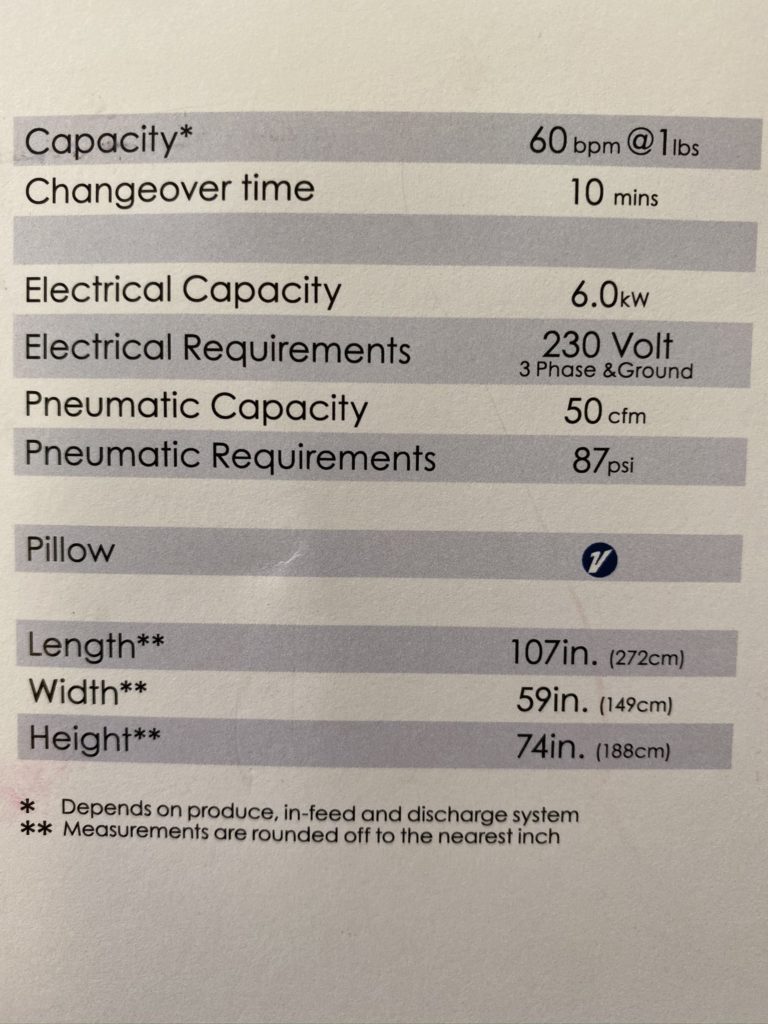

The equipment itself is a “continuous motion vertical form filled and seal packaging machine compatible with the versatile pillow bag style. The machine is designed to operate in flexible production environments; speed optimization with short changeover times guarantee high productivity at the end of the day.”