Paid Advertorial

MSP Onions (1983) was looking for minimal physical labor, 100% traceability and flexible production. Eqraft is realizing a fully automated onion facility, including artificial intelligence, electronic sorting, storage and logistics without forklifts. Packing up to 130 ton per hour with only 10 workers, CO2 neutral and controllable from a tablet.

Eqraft talked with Lindert Moerdijk, owner of MSP Onions. He’s currently leading one of the biggest projects MSP has ever faced: realizing a fully automated onion processing plant according to the principles of Industry 4.0. In this ‘smart factory’, machines take over labor-intensive activities and can be controlled with a comprehensive software layer that links all components of the production process.

Quality and traceability

MSP Onions is a family business located on the Dutch coast in the province of Zeeland, close to the harbor city of Vlissingen. The company was founded in 1983 by the brothers Moerdijk. For the past several years, MSP has been facing the problem of under capacity. Therefore, long-term investments are needed in order to automate. As current owner Lindert explains, “The question is not if Industry 4.0 is coming, but how fast. That’s why we decided to take the plunge and build this ‘factory of the future’ with Eqraft.”

Lindert Moerdijk (MSP Onions) en Rutger Keurhorst (Eqraft)

Lindert tells us about the most important challenges the company is facing nowadays: “Our international clients want high quality and 100% track & tracing for a low price. With the current method of working, the Dutch onion industry cannot fully meet these standards of quality and traceability. That was the trigger we needed to take action.” Delivering onions of constant quality is very hard when you sort the product manually, he explains, and internal quality is impossible to judge with the naked eye. Moreover, watertight tracking and tracing can’t be ensured in the current Dutch onion industry, which keeps the doors closed to collaborations with strictly regulated countries, such as China. Another problem that MSP is currently facing is undercapacity. Labor is expensive and operating every component of the production process with a separate machine and operator isn’t very efficient. When a machine has to be stopped and adjusted manually, it often means interference with other processes or even a full production pause.

Intelligent communication and production with Eqontrol

Wish list for the ideal factory

Taking all of these challenges into account, MSP formulated a ‘wish list’ for their new factory. It wanted a significant improvement in the quality of their onions without increasing the costs per kilogram, full traceability of its products, and workflow automation. Together with Eqraft and the other OTA partners, they began drawing the ideal onion factory from scratch. As Lindert relates, “It wasn’t an easy task. We had to constantly force ourselves to have a totally unbiased vision. That also meant that the first 24 ideas could be scrapped. We really needed to invest, together with OTA. We didn’t make any concessions.” The final result was a factory line that was discussed, improved and engineered to the smallest detail by a group of people with different areas of expertise and different backgrounds. “We can honestly say that this is the best production line possible – not only for our company, but for the entire onion industry,” says Lindert proudly.

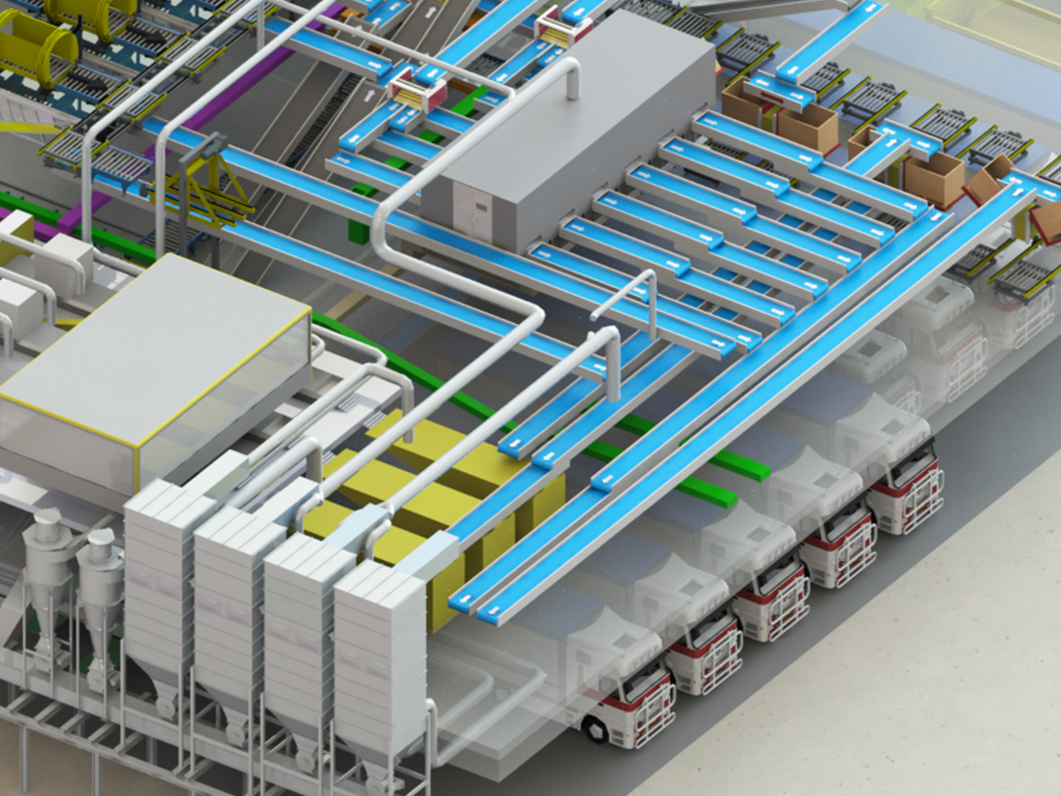

There were quite a few challenges to overcome in designing this ‘factory of the future’. Instead of adjusting the factory plan to fit an existing building, the architecture was optimized according to the process flow at an early stage by loading the 3D drawing of the building into Eqraft’s factory model. However, that also meant that part of the building design had to be changed due to construction regulations, such as fire safety. “The general challenge we faced was that this had never been done before, so you encounter problems you couldn’t have anticipated. I learned to not get nervous, but to keep talking to all parties involved instead. The advantage of working with OTA is that you get the help of real experts in every specialty at every step of the process,” says Lindert.

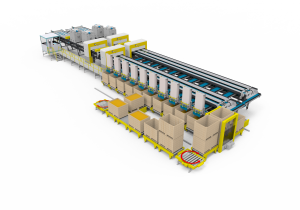

To realize all of this, MSP’s purchases included a 12-lane optical grading production line from Eqraft and several other machines from Modesta and Deprez. The Eqrader ensures quick and accurate sorting based on internal and external qualities, using cameras and infrared scans. Thanks to the use of an intelligent, self-learning neural network, the Eqrader can sort the product based on pre-defined categories depending on the requirements of a specific customer or country, ensuring the high quality that MSP demanded.

“The advantage of working with OTA is that you get the help of real experts in every specialty”

The new MSP Onion Factory

Flexible factory

But the product that will truly make the difference is the additional software layer that enables all machines to communicate with each other intelligently: Eqontrol. The automated instruction process can control several machines and processes simultaneously while preventing interference with other production streams. Because the machines are linked, a simple push of the button is enough to rebuild a line. “That’s new in the onion business,” says Nico Bredenhoff, project engineer at Eqraft. “In most current factories, operators have to move through the factory and set up machines one by one. With Eqontrol, they can simply select the desired outcome on a tablet and the machines do the rest.” Therefore, production can be easily modified according to demand. Custom work and small quantities are much easier and cheaper to realize. Because of the modular factory set-up, the different components are highly flexible; analysts have compared Industry 4.0 factories to Lego kits.

One of MSP’s requirements was a user-friendly interface. “We made the comparison to an iPhone: once you have it in your hand, you intuitively know how it works,” says Lindert. Eqontrol can be used on desktops, tablets and smartphones, enabling the operator to keep an eye on the process and easily check errors. Integrated machine alarms and a graphical presentation of the process give the operator an overview of the problem, so manual action will be required in only extreme cases. That will be the biggest difference, says Lindert: “Manual labor will decrease dramatically. We will save at least 60% of labor costs in the beginning and, in the long run, that will be even more.”

Green innovation

Where sustainability is often seen as a necessary evil, MSP and Eqraft believe sustainability can actually save money. “By fully recycling all waste, we can turn it into something useful: for example, processes that generate heat will be used to warm up the building,” explains Lindert. The new MSP factory will be 100% CO2 neutral.

All in all, the new factory, which is expected to be completed next year, will be a true showcase of innovation. Nico Bredenhoff elaborates: “That’s why we’ll also include a showroom and walking platforms in the factory itself. They follow the journey the onions make, so that we can show visitors how the process works.” Lindert adds: “When it’s finished, the factory will be open for onion traders from all over the world as a meeting point and showcase.”

Go to https://www.eqraft.com/project/msp-onions for the Eqraft website version.

For information:

Norman “Snap” Keene (U.S.)

E-mail: norman.keene@eqraft.com

Harm Geurs (North America)

E-mail: Harm.geurs@eqraft.com

Meet Eqraft at the following events:

June 25-27 United Fresh Show, Chicago (US)

July 10-12 Pulse & Special Crops Convention, Regina (CAN)

July 18-21 NOA Summer Convention, Bakersfield (US)

July 21-24 US Dry Bean Convention, Bonita Springs (US)