Drawing from his background in manufacturing and telecommunications – with a focus on IOT, or Internet of Things, devices – entrepreneur Ehsan Soltan has found a perfect fit for his command of technology in the North American ag industry.

Ehsan was born and educated in the United Kingdom and spent 10 years in Taiwan, where he developed high-tech products for a worldwide customer base. His entrée into ag was by way of marriage, and now he and his start-up company, Soiltech Wireless, are based in Rupert, ID. And with its six-person team – three members in Rupert handling R&D and field operations and three in Taiwan handling R&D and manufacturing – Soiltech “delivers next generation ag-tech solutions designed to drive yields, reduce inputs and generate meaningful data.”

“My wife is from American Falls, ID,” Ehsan said in explaining how he came to ag from a far-removed career. “She is not from an ag family, but her mother is with a large potato cooperative in southern Idaho, which is how I started meeting growers and learning about the potato industry.”

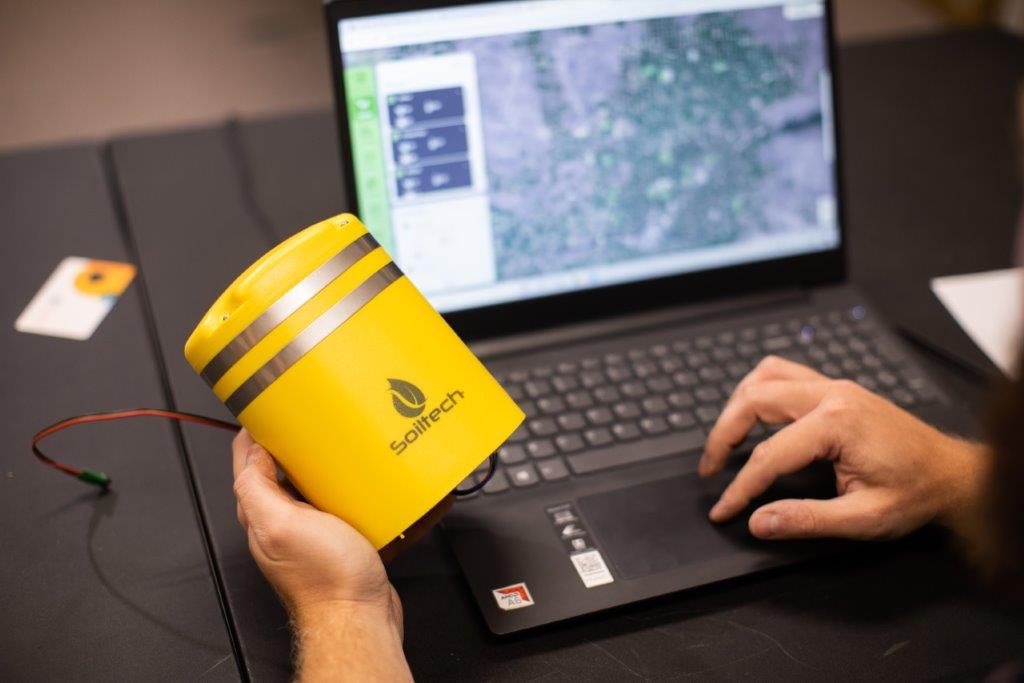

Getting to know the growers meant getting to know their needs, and by working with them he began developing the Soiltech Sensor and App, which progressed from its initial function as a moisture sensor for potatoes into a multi-purpose sensor that can be utilized in virtually any crop, storage or transportation setting.

Its use in the onion industry, Ehsan said, has been customized, and he said onion growers this year “are putting our device under the canopy to monitor humidities. Furthermore, we have introduced an automated growing degree day calculator this year that helps farmers determine planting dates, track plant health and guide them on when to apply fungicides/pesticides.”

At the speed of technology, the Soiltech solution evolved from a concept three years ago into “device with features that provided value across an entire crop production cycle – growth, harvest, transport, storage.”

The sensor, as described in detail at https://www.soiltechwireless.com, “is uniquely positioned to operate throughout the whole ag supply chain from soil to storage, wirelessly monitoring and reporting moisture, temperature, humidity, GPS location and impact data to allow users to manage operations remotely.”

How it works is deceptively simple: The wireless device can be placed either below the surface of the ground or on top and “provides actionable insights without complicated installation – allowing growers and other supply chain participants to view real-time data to drive efficiency and optimize quality.” There are no antennas, gateways or routers required to transmit a signal or send data, and its software automatically calibrates the device based on a layering of GPS location data and NRCS soil maps.

The App is downloadable from the Apple App Store or on Google Play, and the device becomes viewable on the user’s account immediately, “along with real-time data that alerts the business when moisture levels fall outside of preset, customizable ranges.” It’s powered by existing cell towers, and the proprietary software allows growers to manage their operations without any hassles in setup or use of additional equipment.

The device can be brought in out of the field the same time the crop is harvested and then used to track other impacts. Its battery lasts a year before needing recharging. And in addition to monitoring soil moisture levels, the sensor also tracks temperature, bruising, location and humidity – making it an all-crop monitor.

Alerts can be customized to notify the user on “everything from soil type to alert ranges, and safe zones can be adjusted based on the farmer’s knowledge of the field,” the site says. “Suggested ranges come preloaded if a customer prefers a baseline. The ranges are a result of years on the ground working with a network of farm owners and water management experts to test the device.”

Soiltech’s most obvious benefits come in labor and water savings. Ehsan said water is the determining factor for operating expenses, quality, micronutrients and other measurements, and he noted, “Workers will drive hundreds of miles a day just to pick up the dirt. I wanted to create something that would reduce that burden and didn’t require extra work on the part of the grower to learn and manage.”

And one case study shows the system has the “potential to save 500 million gallons of water and 250,000 gallons of gasoline across 10,000 acres of farmland.”

By allowing the user to remotely view the fields and checking data through the App, manpower in general is made more efficient, and the environmental benefits include not only water conservation but also increased efficiency in applications that are tied to irrigation.

Moreover, in addition to viewing the data in real time, a specific range of historical numbers can also be pulled. “Reports can be exported and shared with agronomists and other partners to plan the next season, evaluate equipment performance, and assess current practices, overall helping the business to make more informed decisions.”

How many units are needed per user depends on several factors, among them soil type, irrigation method and the “aggressiveness or comfort level of the user.” We used irrigation methods as our measuring stick, and Ehsan said center pivot might use two to eight units per crop circle. Drip irrigation might use one for every five to 20 acres, and if drip fields are managed in zones, one or two sensors per zone might be used.

“Dryland require fewer units under the soil, but the sensors can be used to track soil temperature prior to planting and also to alert when to add chemicals,” he said.

Most of the Soiltech units now in use for onions are located in the Treasure Valley of Idaho-E. Oregon. “We’re based in nearby Rupert and just launched the product to the market last year,” Ehsan said. However, he added, there are units being used in more than two dozen states and by onion growers and shippers in Vidalia and the Pacific Northwest.

We asked Ehsan what’s on the drawing board, and he said software is being enhanced for crop emergence and disease/pest/stress mitigation.

“We’d like to be a part of overall automating,” Ehsan said. “Our device can act as a trigger to start irrigation. Technically speaking, we can do that right now, and we’re looking to integrate directly with irrigation manufacturers.”

For more information, Ehsan and his team can be reached at 202-705-9993.